Masterbatch, Performance and Sustainability

By adding the pigment to the spinning solution, prior to extrusion, the pigment becomes a homogenous part of the fiber. The dirty and environmentally hazardous process of water dyeing is eliminated from the production process. This production method demonstrates several functional benefits:

- Excellent colorfastness that withstands sunlight, laundry detergent, abrasion, and even bleach.

- Colored yarn opens a whole new world of opportunities in respect to patterns and color combinations when using woven or knitted techniques.

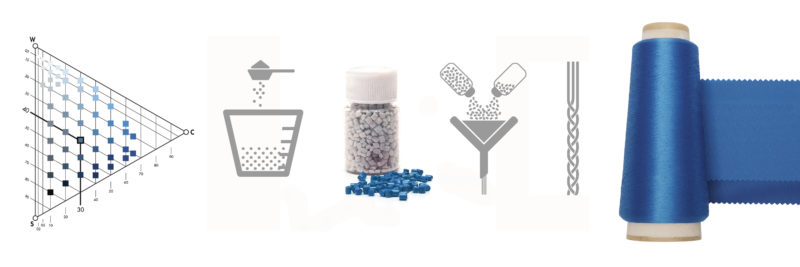

Pick the color out the 1950 colors in the SpinDye®-Color System. This color has its own unique recipe, the color pigment is mixed and highly condensed and becomes our Masterbatch. This is mixed and melted with recycled polyester. Homogeny colored fibers are extruded, spun to yarn and weaved or knitted to fabrics of your desire.

desire

This image shows the full production circle of a garment made by We aRe SpinDye®. We add the color to the polyester mass, in the melting process and extrude a colored fiber, leaving the water completely out of the coloring process.

Photo: Sharon Pittaway