75% less water consumption during the entire coloring process

We aRe SpinDye® colors the textile fiber by melting the color pigment together with the liquid polyester mass. There is no water used in the coloring process which is why we are able to reduce the use of water in the entire fabric production chain by -75%

90% less chemical consumption

We aRe SpinDye® colors the fiber. Because of this, there is basically no waste of color pigments which is why we reduce chemical usage with -90%

Significantly improved energy consumption (30-40%)

Since We aRe SpinDye® cut away the step of dyeing, which is the most energy demanding phase in the whole process – the total amount of energy is reduced with -30%

CO2 imprint reduced by 30%

Since we cut away the most energy demanding phase – the total amount of energy is reduced with -30%. This means we are able to reduce the C02 emissions with -30%

Recycled 100%

We aRe SpinDye® only uses recycled polyester which has been made from post consumer water bottles, or from shredded fabrics from wasted clothes.

We offer an uncomplicated set up of closed loop system with recycled and recyclable polyester

This is truly a circular production method.

Excellent color fastness

Excellent color fastness – longer lifetime – enhanced garment performance

The numbers above are in average. Each batch of fabrics, produced with We aRe SpinDye® get an individual certificate.

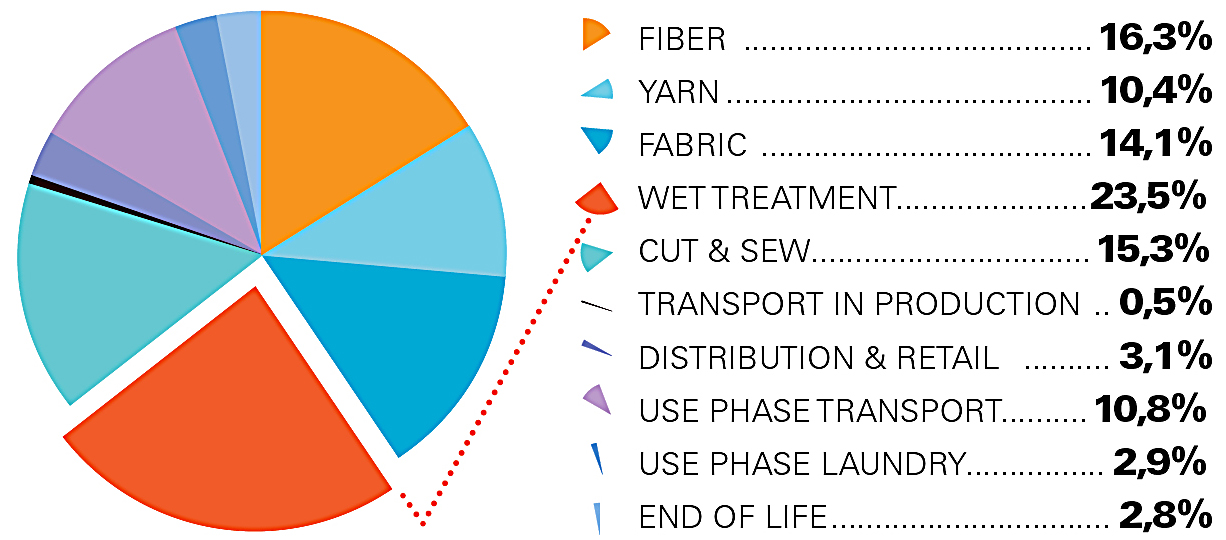

From the Mistra Future Fashion “Outlook Report” ©2020

At present, 80% of a garment’s climate impact stems from the production phase, see info graphic. Furthermore, 92% of the toxicity impact stems from the production phase. In other words, most of the impact happens before the garment hit the store. Therefore, implementing best possible practice is crucial in the production chain, and the garments already produced must stay in use longer.

At present, 80% of a garment’s climate impact stems from the production phase, see info graphic. Furthermore, 92% of the toxicity impact stems from the production phase. In other words, most of the impact happens before the garment hit the store. Therefore, implementing best possible practice is crucial in the production chain, and the garments already produced must stay in use longer.

Out of all steps during production the wet treatment processes have the largest climate impact, see info-graphic. This is due to the large amount of energy required to heat the process water, which often stems from fossil energy sources.

One way to reduce the impact of wet treatments is to completely avoid wet dyeing by adding color pigments already when the fiber is manufactured, so called dope dyeing, spin dyeing or solution dyeing.

All fibers that are extruded (ie man-made fibers such as polyester, nylon, viscose, etc.) can be manufactured this way. Such dry dyeing technique is already available on the market, which means that a reduction in climate impact is a possibility by choice.

A reduction of water usage in the textile preparation phase has several positive effects: reduction in energy use, water use and reduced amounts of contaminated wastewater from the process.

The risk of microplastics shedding from garments during production and use

is minimized if: brushing is reduced, ultrasound cutting is applied in the cut & sew process and microparticles on fabrics are removed already at the production stage.

There is no support for the assumption that fabrics made from recycled polymers shed more than fabrics made of virgin polymers. It might instead be assumed that the concern of fleece material from recycled polyester, thought of as a main cause to the microplastics problem, is explained by the fact that fleece is a material traditionally made from recycled polyester bottles. Using an ultrasonic cutting machine instead of regular scissors when cutting the fabric reduces the shedding with about 50%.

Consider the fact that 7 kg petrol is needed to produce one kg cotton t-shirts. This means that replacing fossil energy in the production chain is seven times more important than replacing fossil textile fibers. From a science perspective, it seems irrational to worry about 100g fossil content in a polyester t-shirt, but not consider the 1000g fossil fuels needed to produce a cotton t-shirt

Photo (top): Aaron Burden